Share Your Project

— Our team is dedicated to addressing customer needs with proficiency and ease, ensuring that every challenge is seamlessly transformed into a solution.

Quality

Machining Solutions

One point

of contact

of contact

24/7 customer

support

support

Stock

material

material

From initial inquiry to the final delivery of the product, we will serve as your trusted partner, ensuring that all your requirements are meticulously met.

— Our team is dedicated to addressing customer needs with proficiency and ease, ensuring that every challenge is seamlessly transformed into a solution.

Quality

Machining Solutions

One point

of contact

of contact

24/7 customer

support

support

Stock

material

material

From initial inquiry to the final delivery of the product, we will serve as your trusted partner, ensuring that all your requirements are meticulously met.

PORTFOLIO

R&H Machine fabricates plug catchers of various sizes. Durable, corrosion-resistant, and easy to maintain, these plug catchers stand up to the harsh environments they were built for.

Avoid expensive disposal of kill fluids with R&H Machine's mini snubbing units. For use in both onshore and offshore equipment, we have several units, from 150k to 330k pounds full force.

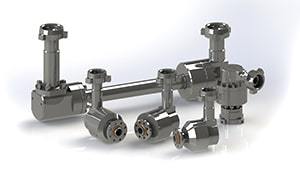

Our high-pressure swivels are created to stand the test of time and pressure. They are durable and reliable, and because of this they are used in workover and coil tubing applications throughout the oil and gas industy. Pressure tested at 8.5k or 15k psi, giving you peace of mind and safety for your field personnel.

PLUG

CATCHERS

CATCHERS

SWIVELS

MINI SNUBBING

UNITS

UNITS

SERVICES

Our highly-skilled team is quick to site when a repair is needed on your well. From pump down to gear brakes to pump jacks, our technicians have you covered.

EQUIPMENT

REPAIR

REPAIR

WELDING

& FABRICATION

& FABRICATION

CNC

MACHINING

MACHINING

Our welders are well-versed in the various methods and aspects of welding and use the best methods available for your projects. Our fabrication team is here to help you recreate your parts as needed for a clean retrofit.

CNC Machining comes in many varieties today. Our team has experience with Manual Machining, CNC Turning and Milling, CNC 3&4 Axis Machining, Plasma Cutting, Hydrostatic testing, and Stress Relieving.

With a diverse line of equipment, designed to meet the industry's needs, and a team dedicated to solving any challenge, your projects are finished on time and on budget.

Our highly-qualified and certified team strives to exceed your expectations on each and every project.

Our highly-qualified and certified team strives to exceed your expectations on each and every project.

WE EXCEL IN

Leveraging over two decades of experience, our machining and fabrication capabilities, along with our diverse product lines, have been meticulously crafted to cater to your specific needs, securing precision and excellence in every aspect.

MACHINING

FABRICATION

OEM PARTS

(on-site / off-site)

FAQ

What type of files do you need for quoting a machining or fabrication job?

STEM files are preferred; however, we can quote the job with a drawing or sketch of any sort. Old sketches from similar or previous projects can also be used to quote.

Do you need CAD files for CNC Machining?

Yes. Our CNC machines use CAD (computer-aided design) files to ensure a precision cut. We prefer STEM files, but if you do not have STEM files available, we can work with you to produce them. We can create your drawings for a small additional fee.

Can you help with reverse engineering?

Yes. We keep this process in-house, with our trusted employees. We are capable of reverse engineering many of the products you currently use.

What materials can be CNC Machined?

Steel is a common material that is used. We can also use Aluminum, Copper Alloys, Titanium, and Nickel Alloys. Our capabilities are not limited, and we work with both standard and exotic materials.

OUR

GOAL

GOAL

— is to become your premier, all-in-one provider for machining, fabrication, and original equipment manufacturer (OEM) parts, delivering comprehensive solutions tailored to your needs.

OUR

MISSION

MISSION

— is to excel in serving you, consistently elevating the quality and safety of every product to the forefront of our priorities, ensuring your experience is nothing short of exceptional.

OUR BLOG

APPLY FOR JOBS

CNC Lathe Machinist

This position is responsible for fabricating new and replacement parts. The position summary is to be used as a guideline only and may not incorporate all functions of the job.

Manual Machinist

This position is responsible for operating machines and producing complex production and prototype parts to high tolerance design. The position summary is to be used as a guideline only and may not incorporate all functions of the job.

MACHINING

FOR YOU

FOR YOU

At R&H Machine and Fabrication, we are fully equipped to elevate your projects with our state-of-the-art CNC Machining, CNC Turning, and CNC Lathes, poised for precision performance. For less complex tasks, our manual machining stands ready to efficiently tackle your simpler projects. For robust applications involving thicker metals, our advanced plasma cutter is at your disposal. Whatever the scope of your project, R&H Machine and Fabrication is your comprehensive solution for all machining, fabrication, and equipment repair needs, ensuring unparalleled quality and service.

One

point of

contact

point of

contact

24/7

customer

support

customer

support

Stock

material

material